The goods inbound process is one of the most critical and costly bottlenecks in the entire supply chain. Delays, counting errors, and a lack of visibility into incoming shipments create inefficiencies that impact the entire warehouse.

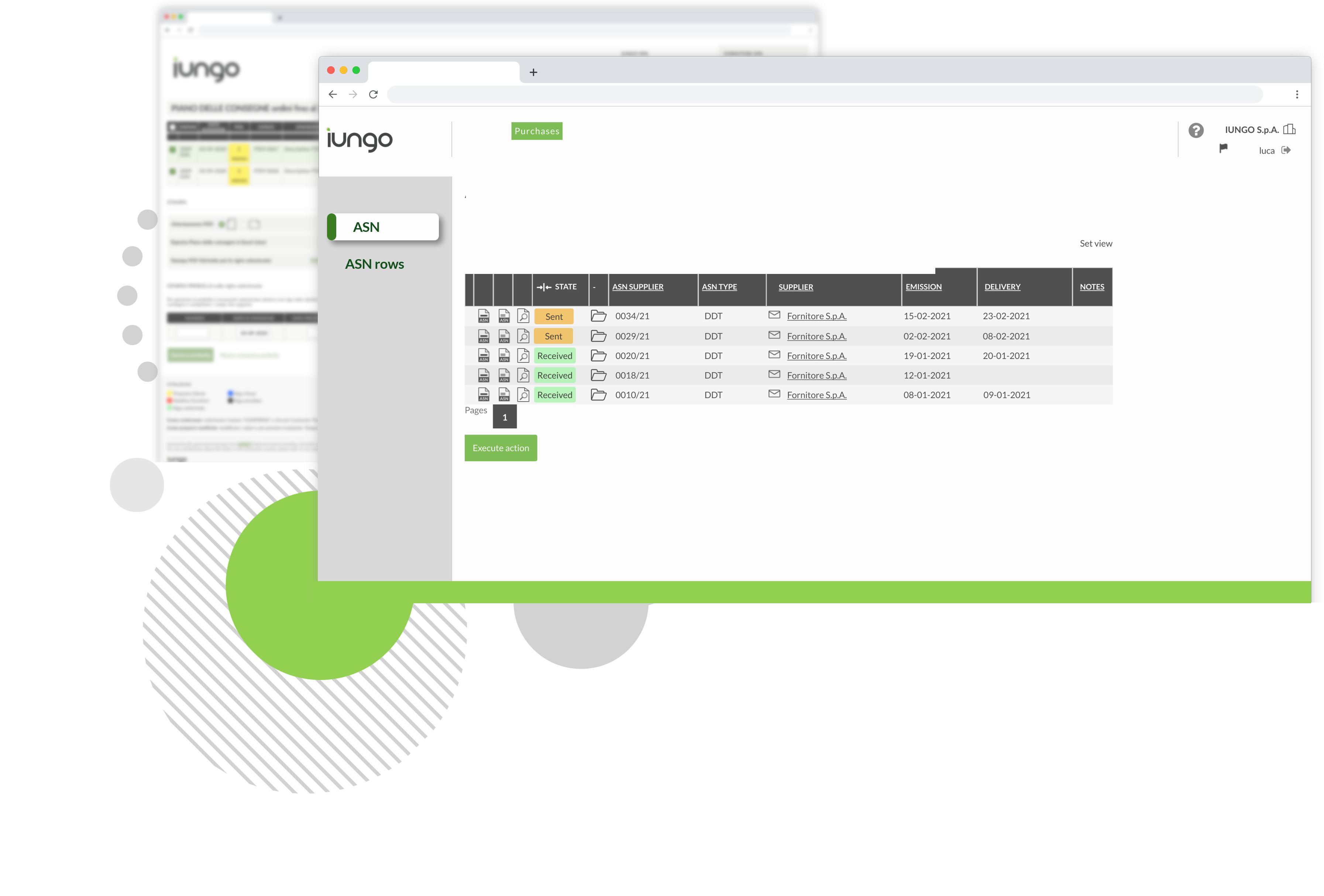

IUNGO’s logistics and warehouse software transforms this process. Through digital management of Advanced Shipping Notices (ASNs) and standardization of logistics labels, IUNGO connects your suppliers directly to your warehouse, ensuring an anticipated, accurate, and automated flow of information.